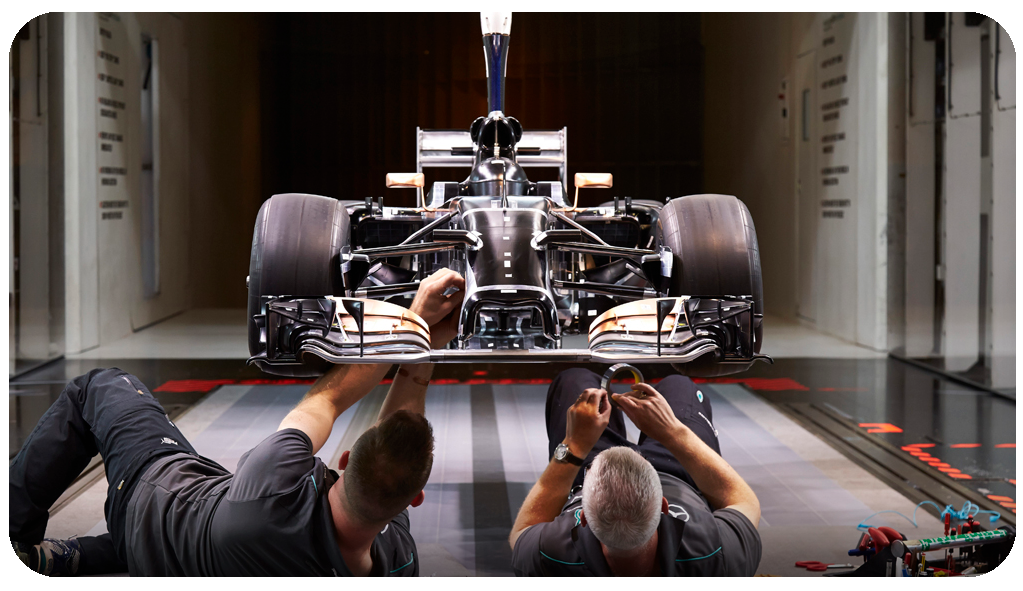

The Wind Tunnel Model #

Scale wind tunnel model of a Mercedes W05. Photo courtesy of Mercedes-Benz Grand Prix Ltd.

Introductory Thoughts #

Often times, for a ongoing development program, a bespoke wind tunnel model of the vehicle is used rather than a working prototype. This is because an actual racecar car doesn’t have the provisions needed to allow wind tunnel testing, provisions such as modularity of body panels (to be easily fitted and removed), and to mount the signficant instrumentation equipment required.

Designing, building and maintaining this model is an expensive proposition. For example, to test variations of a cars front end, each variation would have to be full 3D printed nose. This is an excessive burden for even the most well funded organizations.

Scale Model Benefits #

A work around is to to test in a scale wind tunnel. Most scale models hover around ~50% scale. This means they are half as long, half as wide, and half as tall. Because volume follows a cubic relationship, a 50% scale model needs 1/8 the volume of material compared to a full scale model. This is a much more reasonable proposition.

-IMAGE-

The size of the model can’t just be reduced without other provisions to make up for the accuracy. To have the scale wind tunnel phenomenon align with full scale, the speed of the flow has to be increased proportionate to what scale is being used. So for 50% scale, the velocity has to be doubled. Often times this is a difficult thing to achieve (doubling the airspeed requires quadruple the energy). An attempt to speed up the velocty is usually made, but often times good results can be achieved even with a mismatch.

X Photo courtesy of X.

Scale Wind Tunnel Tires #

Wind tunnel tires have a very long working life. A tunnel tire set can easily last for a distance longer than a tour around the globe.

A scale tire has to deform in a manner similar to the real tire.

Active loading systems are placed inside the towers.

The scale tire has to defor accurately under extreme loads.